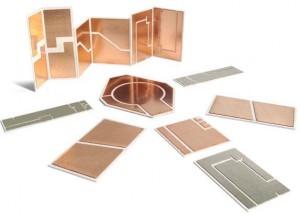

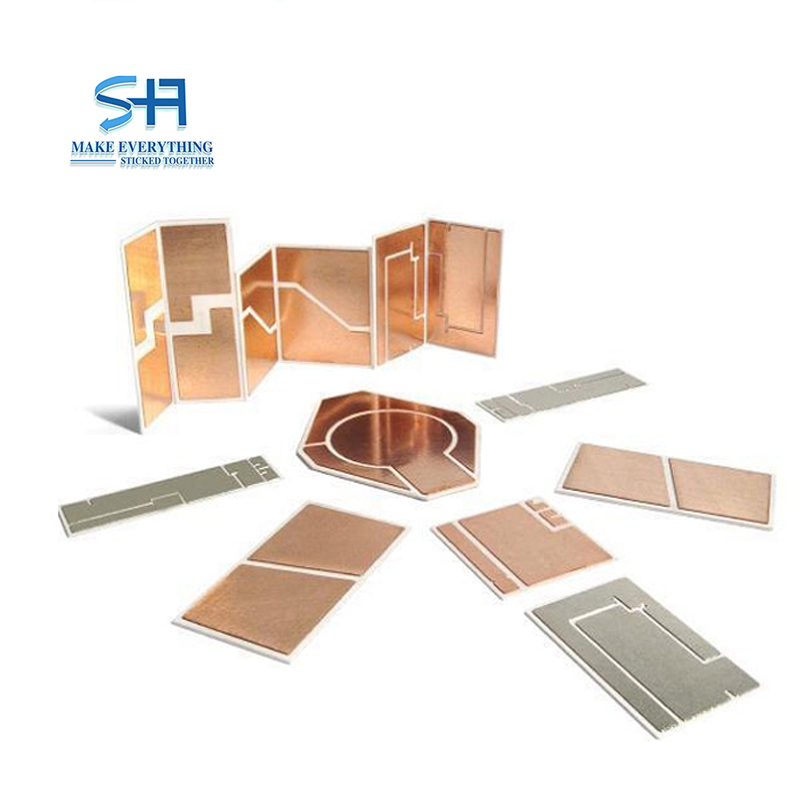

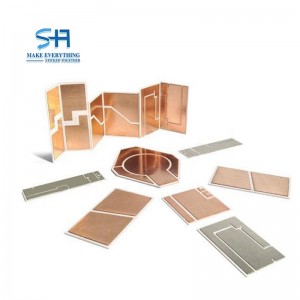

25 mm width Pure copper foil tape with conductive adhesive

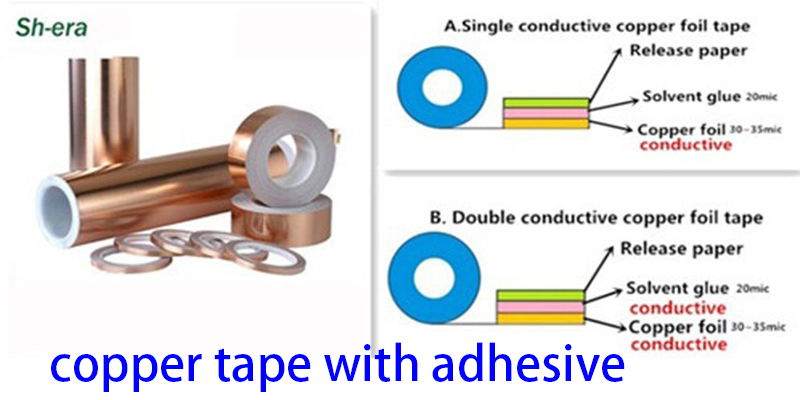

Copper foil tape is divided into single-sided adhesive coating and double-sided adhesive coating. Single-sided coated copper foil tape is divided into single-conductor copper foil tape and double-conductor copper foil tape. Single-conductor copper foil tape means that the coated surface is not conductive, and only the other side is conductive, so it is called single-conductor means single-sided conductive ; Double-conductor copper foil tape refers to the conductive surface (conductive acrylic adhesive), and the other side of the copper itself is also conductive, so it is called double-conductivity, which means double-sided conduction.

There are also double-sided adhesive-coated copper foil tapes that are used to process more expensive composite materials with other materials. The double-sided adhesive-coated copper foil also has two types of adhesive surfaces: conductive and non-conductive. Customers can choose according to their own needs for conductivity.

How to distinguish the single conductive copper foil tape and the doubel sided conductive copper foil tape ?

Single and double conductive copper foil conductive tape can be distinguished from the following two methods:

1. From the appearance: tear off the copper foil tape for a short section to see the adhesive surface

The adhesive surface of the single-lead copper foil tape has no small metal particles and is flat;

Double-lead copper foil tape, the adhesive surface contains small metal particles (metal particles, which play a conductive role), which is slightly uneven;

2. Pass the test: Use a low-resistance tester to measure, the general resistance value of the double-conductor copper foil tape is 0.01-0.03Ω, and the single-conductor copper foil tape will not have current through it.

Applications for this copper foil tape are as follows:

1) Antistatic floor (ESD floor);

2) Shielding in housings and Faraday cages.