Autoclave Indicator Tape

Detailed description

Autoclave tape is an adhesive tape used in autoclaving (heating under high pressure with steam to sterilise) to indicate whether a specific temperature has been reached. Autoclave tape works by changing color after exposure to temperatures commonly used in sterilization processes, typically 121°C in a steam autoclave.

Small strips of the tape are applied to the items before they are placed into the autoclave. The tape is similar to masking tape but slightly more adhesive, to allow it to adhere under the hot, moist conditions of the autoclave. One such tape has diagonal markings containing an ink which changes colour (usually beige to black) upon heating.

It is important to note that the presence of autoclave tape that has changed color on an item does not ensure that the product is sterile, as the tape will change color upon exposure only. For steam sterilization to occur, the entire item must completely reach and maintain 121°C for 15–20 minutes with proper steam exposure to ensure sterilization.

The color-changing indicator of tape is usually lead carbonate based, which decomposes to lead(II) oxide. To protect users from lead -- and because this decomposition can occur at many moderate temperatures -- manufactures may protect the lead carbonate layer with a resin or polymer that is degraded under steam at high temperature.

Characteristic

- Strong stickiness, leaving no residual glue, making the bag clean

- Under the action of saturated steam at a certain temperature and pressure, after a sterilization cycle, the indicator turns gray-black or black, and it is not easy to fade.

- It can be adhered to various wrapping materials and can play a good role in fixing the package.

- The crepe paper backing can expand and stretch, and it is not easy to loosen and break when heated;

- The backing is coated with a waterproof layer, and the dye is not easily damaged when exposed to water;

- Writable, the color after sterilization is not easy to fade.

Purpose

Suitable for low-exhaust pressure steam sterilizers, pre-vacuum pressure steam sterilizers, paste the packaging of the items to be sterilized, and indicate whether the goods packaging has passed the pressure steam sterilization process. To prevent mixing with unsterilized packaging.

Widely used in the detection of sterilization effects in hospitals, pharmaceuticals, food, health care products, beverages and other industries

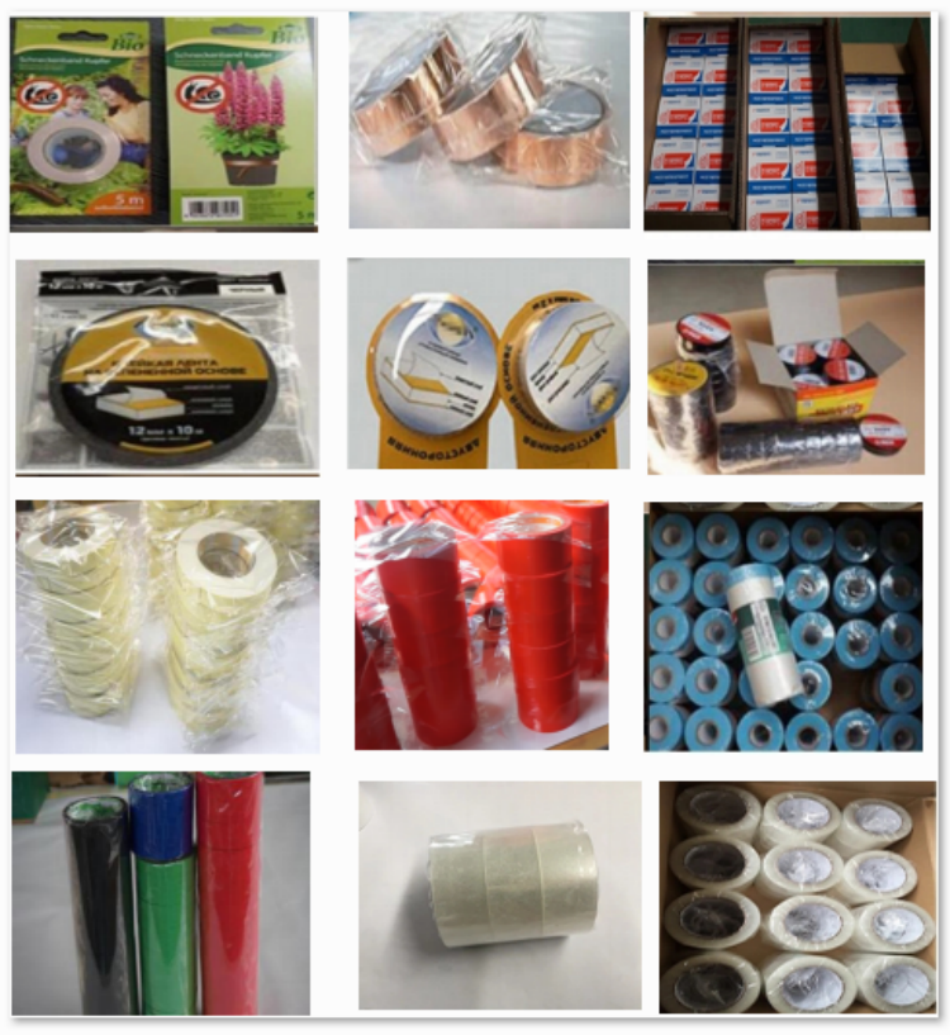

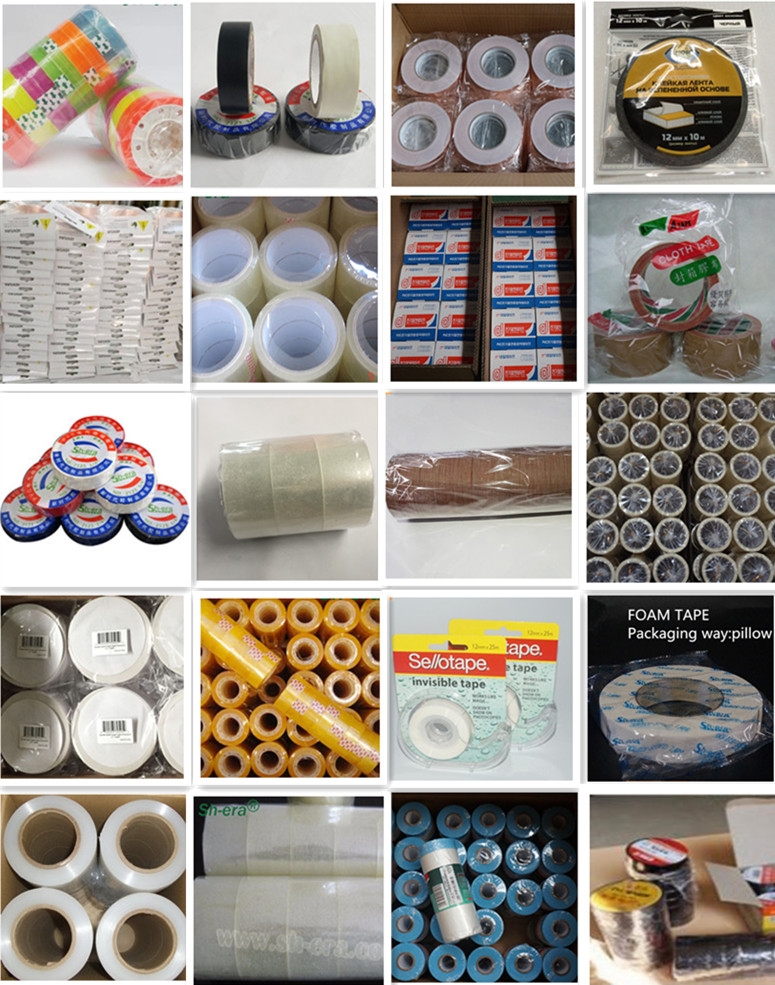

Recommended Products

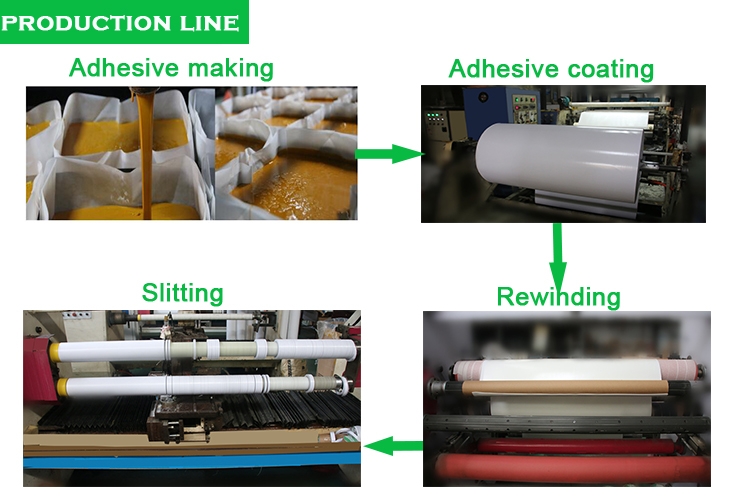

Packaging Details