EVA Hot Melt Glue Stick for Packaging and Woodworking Bonding in DIY Draft

Features of hot melt glue stick

1. The hot melt glue stick has fast bonding speed, convenient for continuity, automatic high-speed work, and low cost.

2. No solvent pollution and no burning.

3. No drying process is required, and the bonding process is simple.

4. The product itself is solid, which is convenient for packaging, transportation and storage, with a small footprint and convenient storage.

5. It has good bonding strength and flexibility.

6. A wide range of bonding objects, that is, bonding and sealing.

7. Good gloss and gloss retention, good shielding performance.

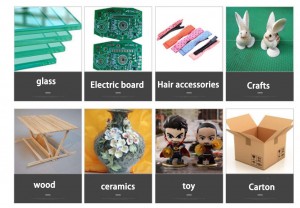

Application range of hot melt glue stick

Used for bonding plastic, metal, wood, paper, toys, electronics, furniture, leather, handicrafts, shoe materials, coating, ceramics, lampshades, pearl cotton, food packaging, speakers, etc., through hot melt glue gun, hot melt The glue machine is used.

How to use hot melt glue stick

1. The hot melt glue stick should be used with a glue gun. First, use the hot melt glue gun to glue.

2. Then put the glue stick into the hot melt gun and plug in the electric heating for a while.

3. At this time, when the trigger is pulled, there will be glue flowing out of the muzzle.

4. We can also directly burn one end of the hot melt glue stick with a lighter, apply it to the place where it is to be glued, and wait for the glue to become solid. Using hot melt glue stick to bond paper cartons, handicrafts, hand-made, etc., is convenient and easy to use, and is stronger than ordinary glue.

Matters needing attention in the selection of hot melt glue sticks

1. Glue sticks with poor quality can still be seen with the naked eye, such as uneven color and obvious impurities inside. The price of a thick glue stick is generally less than one dollar. Compared with a good glue stick, the color is uniform, no impurities can be seen inside, and some numbers are printed on the glue stick. A good thick glue stick is generally more than one dollar.

2. The color of the glue stick is also different. It is generally consistent with the color of the adherend. If there is no special requirement, it is recommended to use yellow hot melt adhesive. Generally speaking, yellow hot melt adhesive has better viscosity than white.

3. Surface treatment of the adherend. The surface treatment of the hot melt adhesive is not as strict as other adhesives, but the dust and oil on the surface of the adhered object should also be properly treated to make the hot melt adhesive play a better role in bonding.

4. Operating time. Fast operation is a major feature of hot melt adhesives. The working time of hot melt adhesive is generally about 15 seconds. With the extensive use of modern production methods-assembly lines, the working time requirements for hot melt adhesives are getting shorter and shorter, such as book binding and speaker manufacturing for hot melt adhesives. It is required to reach about 5 seconds.

5. Resistance to temperature. Hot melt adhesives are sensitive to temperature. When the temperature reaches a certain level, the hot melt adhesive begins to soften. Below a certain temperature, the hot melt adhesive will become brittle. Therefore, the choice of hot melt adhesive must fully consider the temperature change of the environment where the product is located.

6. Stickiness. The viscosity of hot melt adhesive is divided into initial viscosity and late viscosity. Only when the initial viscosity is consistent with the late viscosity can the hot melt adhesive and the substrate remain stable. In the production process of hot melt adhesive, it should be ensured that it has resistance to oxygen, halogen, acid and alkali, and plasticity. Depending on the material to be bonded, the viscosity of the hot melt adhesive is also different. Therefore, different hot melt adhesives should be selected according to different materials.