When talking about hot melt adhesives, glue sticks and dispensers, people tend to think of its handicraft applications. Although most of us may be introduced to hot glue during the process, it is one of the most commonly used adhesives in industrial manufacturing. Industrial hot melt adhesive is one of the most widely used adhesives on the market. Its fast drying time, flexibility and strength make it a recommended choice for many manufacturers.

1、Bookbinding

As we all know, hot melt glue is usually used for binding books. There are many ways to bond paper and cover together, and industrial hot melt adhesives are an excellent choice due to their fast drying speed and flexibility.

2、Woodworking

Craftsmen and carpenters often come into contact with hot melt adhesives when working on projects. Once cured, the bond strength of industrial hot glue will exceed 1,000 pounds. It also adheres well to porous and non-porous materials, making it easy to bond laminates, wood, chipboard, foam, medium density fiberboard and fabrics.

This strength and versatility make hot melt adhesives the first choice for laminating trims, mountings, small seams and surfaces to furniture. The almost instant bond strength of hot melt adhesives helps increase production speed while eliminating unnecessary screws, ties and nails.

3、Food carton packaging and sealing

Since the 1960s, hot melt adhesives have been the darling of the food packaging industry. Generally, hot melt adhesive is used to close large and small cartons and parcel boxes. Industrial hot glue has good adhesion on packaging, short setting time and high water resistance, which can simplify the packaging process.

4、Frozen food packaging

From the store to the table, the journey of frozen food is quite difficult. The packaging must be able to withstand a lot of wear and tear, usually after being filled, transported, displayed, and stuffed into the refrigerator once purchased. In order to ensure that the food is not damaged or deteriorated, frozen food packaging requires a strong adhesive, and hot melt adhesive plays a good role here.

5、Seal envelopes, bags and cardboard

The strong bonding force produced by hot melt adhesive is very suitable for fixing paper, cardboard and other cellulose materials. Whether it is applied manually or using a hot melt adhesive dispensing system, hot glue provides long-lasting and flexible retention, making it ideal for bonding paper surfaces. Therefore, the manufacture of envelopes, corrugated cardboard and paper bags will rely on industrial hot melt adhesives.

6、attach a label

The application of hot-melt adhesive to labels is very common in our lives. Labels like mineral water bottles are glued by hot-melt adhesive. Industrial hot glue is used to quickly bond paper-lined film to plastic. The fast drying speed and simple application process make hot melt adhesives suitable for fast and cost-effective label application.

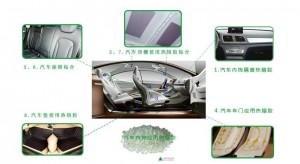

7、Transportation

Due to the high temperature resistance of hot melt adhesives, hot melt adhesives are also involved in the automotive industry. Automotive decorative edges, small joints, adhesive laminate surfaces and other components are all applied to hot melt adhesives.

8、Leather and Footwear

Hot melt adhesive is also widely used in the footwear industry. It is mainly used for bonding insoles, fixing shoe tongues, adhering foam to the inside and bonding accessories to the outside of shoes.

9、Textile manufacturing

In the production of synthetic fabrics, there is also a place for hot melt adhesives, which are usually used for polymer

Textile transformation in industrial and automotive, home decoration, carpet and other textile manufacturing applications.

Post time: Jan-16-2021