Many parts in the manufacture of solar photovoltaic require tape. From the bonding of the frame of the solar photovoltaic module, the fixing of the bracket on the back of the module, the permanent edge protection, the fixing and arrangement of the solar cell, the fixing of the wiring harness of the junction box, the fixing of the junction box, the fixing and insulation of the bus bar, the shielding of the conductive lead, the temporary shielding hole, etc , All apply a variety of different tape products.

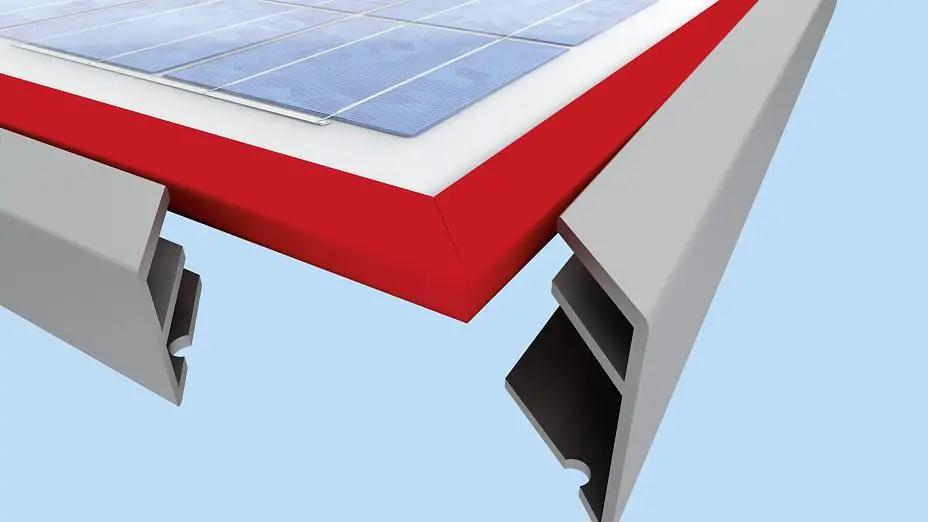

For Solar frame bonding

Double-sided PE foam tape is the key to achieving high-quality and reliable bonding performance. The PE foam substrate ideally balances high compliance and high cohesive strength. The optimized acrylic adhesive can firmly bond most backplanes and is easy to apply.

Required tape: PE foam tape

- Safe and stable frame fixing;

- No warping, avoid work stoppage or rework;

- Anti-UV, waterproof, anti-aging, weather resistance;

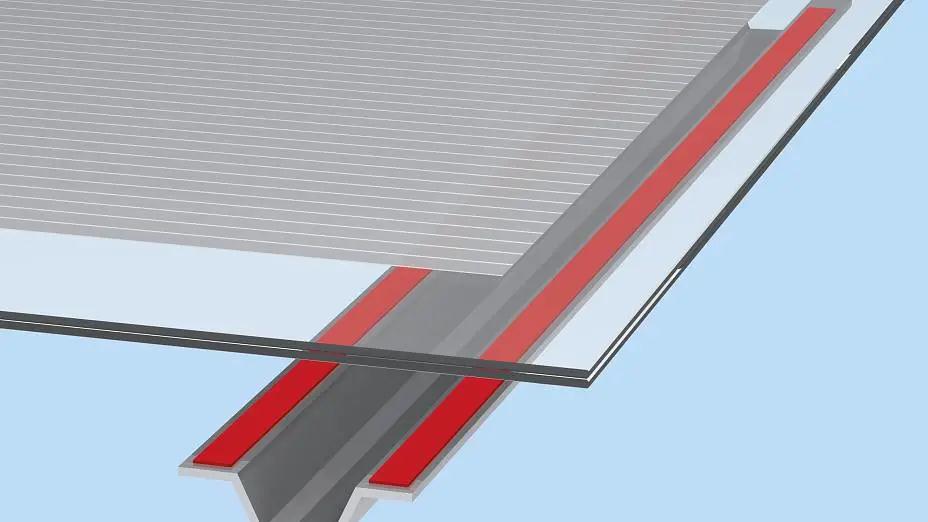

Fixing of the bracket on the back of the module

It is a reliable and permanent fixation solution for the fixing of the bracket on the back of the module, the condenser and the heliostat. No curing time required, faster installation.

Required tape: black PE foam tape

Clean working environment, convenient application, fast bonding, no drying or curing, reliable and efficient production process

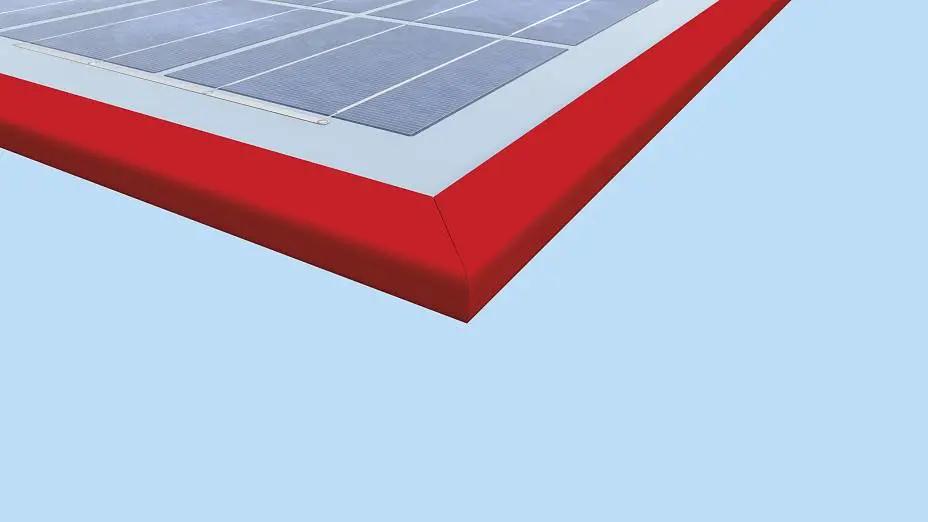

Permanent edge protection

Frameless PV modules with glass backplanes are an attractive new product; however, the glass edges are easily damaged during production, transportation, and installation.

The edge protection tape makes the frameless photovoltaic module have a beautiful appearance, reduces the damage rate of the module, seals, and prevents water seepage or delamination.

Required tape: Matte black single-sided tape (PET tape)

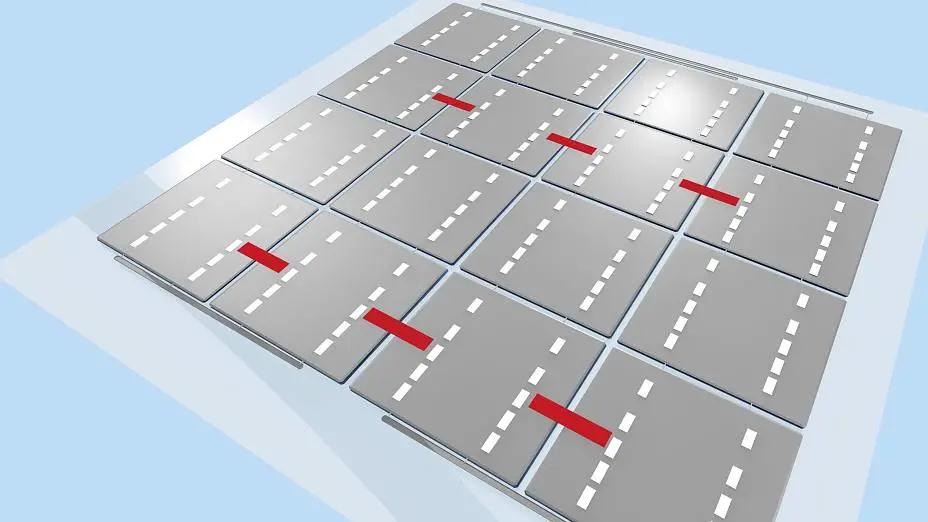

Cell fixing and arrangement

During the lamination process, the cells must be kept fixed, and the wiring harness must be neatly arranged. Since the product will remain inside the PV module, it must have good anti-aging and anti-ultraviolet properties.

During the lamination process, keep the position between the solar cells; fix and insulate the solar ribbon in the thin film module.

Required tape: PET tape

The junction box is installed and fixed

Use PE foam for instant fixation when the junction box is installed, improving process safety and bonding quality. Solve the problem of quality problems caused by the curing time when the junction box is sealed with silica gel, such as displacement of the junction box or insufficient curing process. Moreover, the foam tape is UV resistant, weather resistant, smooth and beautiful.

Required tape: PE foam tape

Shanghai Newera Viscid Product Co.,Ltd has specialized in adhesive tape for 30 years, covering 14 kind of adhesive tape, here is our website: http://www. tapenewera.com

Welcome to contact us!

Post time: Apr-27-2021