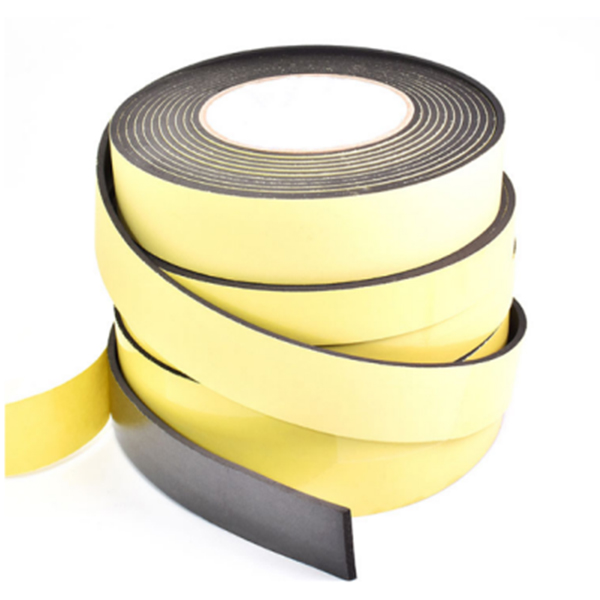

Foam tape is a versatile adhesive product that has gained popularity across various industries and applications. Made from materials like polyethylene, polyurethane, or EVA (ethylene-vinyl acetate), foam tape is characterized by its cushioning properties, flexibility, and ability to conform to irregular surfaces. This article will explore the various uses of foam tape and provide guidance on how to choose high-quality EVA foam tape.

What is Foam Tape Good For?

1. Sealing and Insulation

One of the primary uses of foam tape is for sealing gaps and providing insulation. Its compressible nature allows it to fill voids and create a tight seal against air, dust, and moisture. This makes foam tape an excellent choice for weatherproofing windows and doors, preventing drafts, and reducing energy costs. In HVAC systems, foam tape can be used to seal ductwork, ensuring efficient airflow and minimizing energy loss.

2. Cushioning and Protection

Foam tape is widely used for cushioning and protecting delicate items during shipping and handling. Its soft, compressible structure absorbs shocks and vibrations, making it ideal for packaging fragile products like glassware, electronics, and ceramics. Additionally, foam tape can be applied to surfaces to prevent scratches and damage, making it a popular choice for furniture and automotive applications.

3. Mounting and Bonding

Foam tape is an effective mounting solution for various materials, including metal, plastic, glass, and wood. Its strong adhesive properties allow it to bond securely to surfaces, making it suitable for mounting signs, displays, and other objects. Double-sided foam tape, in particular, is favored for its ability to create a clean, invisible bond, making it ideal for crafts, home décor, and DIY projects.

4. Vibration Dampening

In industrial applications, foam tape is often used to dampen vibrations and reduce noise. By applying foam tape to machinery, equipment, or vehicles, operators can minimize the impact of vibrations, leading to improved performance and longevity. This is particularly important in manufacturing settings where machinery operates at high speeds or generates significant noise.

5. Electrical Insulation

EVA foam tape is also used in electrical applications due to its insulating properties. It can be applied to wires, connectors, and circuit boards to prevent short circuits and protect against moisture. Its flexibility allows it to conform to various shapes, making it suitable for a wide range of electronic devices.

How to Choose Good Quality EVA Foam Tape

When selecting EVA foam tape, it’s essential to consider several factors to ensure you choose a product that meets your specific needs. Here are some key considerations:

1. Thickness and Density

The thickness and density of foam tape can significantly impact its performance. Thicker tapes provide better cushioning and insulation, while denser tapes offer stronger adhesion and durability. Consider the application when choosing the thickness and density of the foam tape. For example, if you need to fill larger gaps, a thicker tape may be more suitable, while a thinner tape may suffice for smaller applications.

2. Adhesive Strength

The adhesive strength of foam tape is crucial for its effectiveness. Look for tapes with high initial tack and shear strength to ensure a secure bond. Depending on your application, you may need a tape with a permanent adhesive or one that allows for repositioning. Always check the manufacturer’s specifications to determine the adhesive’s suitability for your intended use.

3. Temperature Resistance

If you plan to use foam tape in environments with extreme temperatures, it’s essential to choose a product that can withstand those conditions. EVA foam tape typically has good temperature resistance, but it’s still important to verify the temperature range specified by the manufacturer. This is particularly important for applications in automotive or industrial settings where heat exposure is common.

Post time: Nov-28-2024