What is double-sided tape?

The main purpose of double-sided tape is to stick the surfaces (contact surfaces) of two objects together, which can be divided into temporary fixing and permanent bonding according to actual requirements. Double-sided tape is a roll-shaped adhesive tape made of paper, cloth, film, foam, etc. as the base material, and then evenly coating the adhesive on both sides of the above-mentioned base material. Paper (release film) consists of three parts. Depending on the substrate, some substrates require surface treatment before gluing.

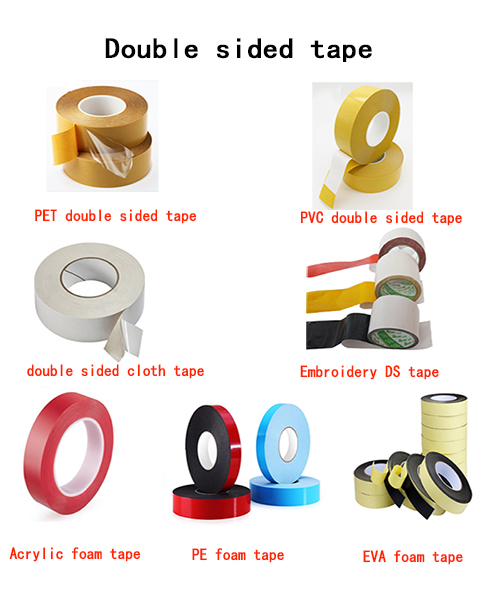

Due to the wide selection of substrates and adhesives and the possibility of different combinations, there are more types of double-sided tapes than other types of tapes.

Overview of the classification and characteristics of double-sided tape:

1. PET Double-sided tape : good temperature resistance and strong shear resistance, generally long-term temperature resistance 100-125 °C, short-term temperature resistance 150-200 °C, thickness is generally 0.048-0.2MM, suitable for nameplate, Bonding of LCD, decorations and decorative parts.

2. Non-woven double-sided tape( tissue paper double sided tape) : good viscosity and processability, generally long-term temperature resistance of 70-80 °C, short-term temperature resistance of 100-120 °C, thickness is generally 0.08-0.15MM, suitable for nameplate, plastic Lamination, automotive, mobile phone, electrical appliances, sponge, rubber, signage, paper products, toys and other industries, home appliance and electronic instrument parts assembly, display lens.

3. Double-sided adhesive without substrate: It has excellent adhesion effect, can prevent falling off and excellent waterproof performance, good processability, good temperature resistance, short-term temperature resistance of 204-230 °C, and general long-term temperature resistance of 120-145 °C , the thickness is generally 0.05-0.13MM, suitable for the bonding of nameplates, panels and decorative parts.

4. Foam double-sided tape: refers to a kind of double-sided tape formed by applying strong acrylic adhesive on both sides of the foamed foam substrate, and then covering one side with release paper or release film. Forming paper or release film is called sandwich double-sided tape, and sandwich double-sided tape is mainly used to facilitate double-sided tape punching. Foam double-sided tape has the characteristics of strong adhesion, good retention, good waterproof performance, strong temperature resistance and strong UV protection. Foam foam substrates are divided into: EVA foam, PE foam, PU foam, acrylic foam and high foam. The glue system is divided into: oil glue, hot sol, rubber and acrylic glue.

5. Hot melt adhesive film: It has good consistency, uniform bonding thickness, no solvent, easy processing, good adhesion to many objects, thickness is 0.1MM, color is translucent/amber, hot Melt softening temperature 116-123 ℃. It is suitable for the bonding of nameplates, plastics and hardware. Good results can also be obtained by bonding on uneven surfaces. The recommended initial bonding conditions are: temperature 132-138 ℃, bonding time 1-2 seconds, pressure 10 -20 psi.

Post time: Mar-15-2022